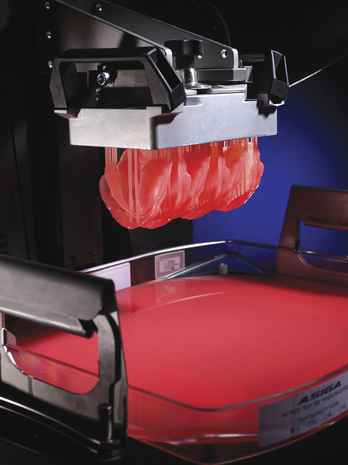

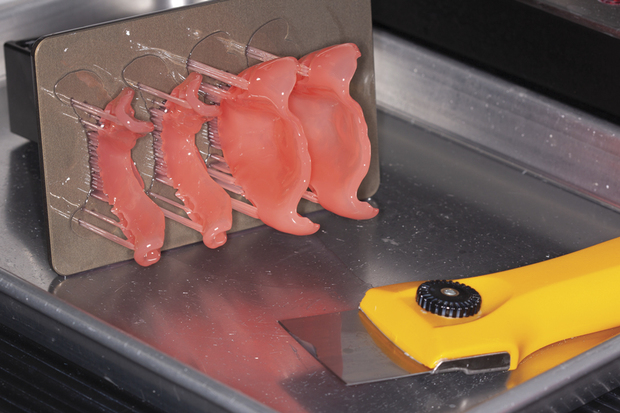

Step 10 - Gently snap off the support material from the denture base and teeth with your fingers. Smooth and contour the small nibs from the supports on the base and teeth so that the printed teeth fit precisely into the denture base sockets. I use carbide burs, rubber points and wheels, and Scotch Brite wheels.

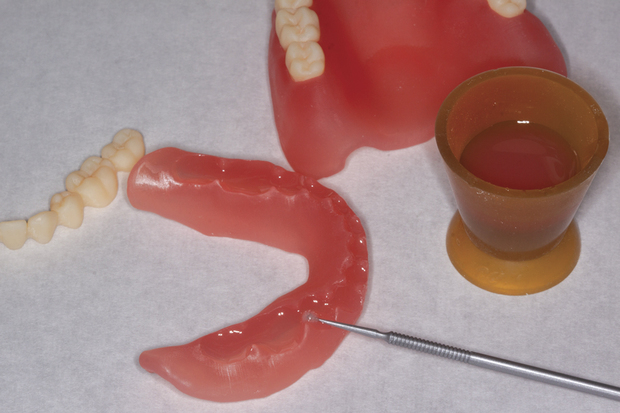

Step 14 - This is an optional step: to enhance the esthetics, I use Anaxgum and Anax Paint Flow to tint the denture base, GC Opticolor Glaze to characterize the teeth and base and Dreve Nano Varnish to glaze and seal the composite layering. These products are from anaxdent North America, GC America and Dreve respectively.