Step 9:

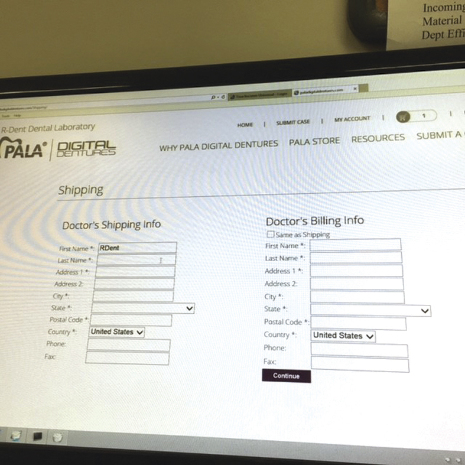

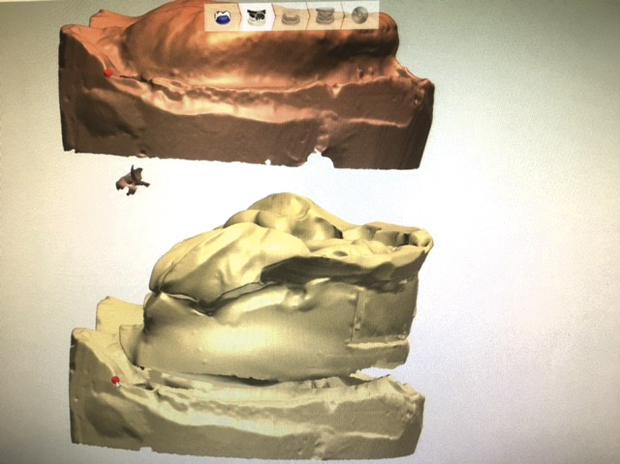

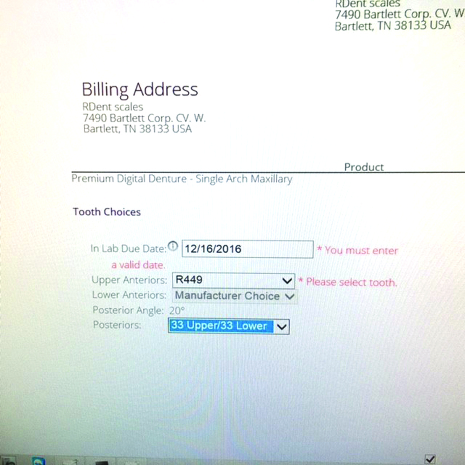

My Digital Denture can be made with Heraeus Kulzer’s Mondial, Mondial i or Artic Digital teeth; for this case, Guardiola selected Mondial teeth in Heraeus Kulzer shade A1 with a pink denture base. He submitted the order along with the digital impression file to Heraeus Kulzer’s Pala Digital Design Center in South Bend, IN, for design. — tagged Mondial® and Mondial® i Teeth and Signum® HiLite® power 3D & HiLite® Pre 2Step 11:

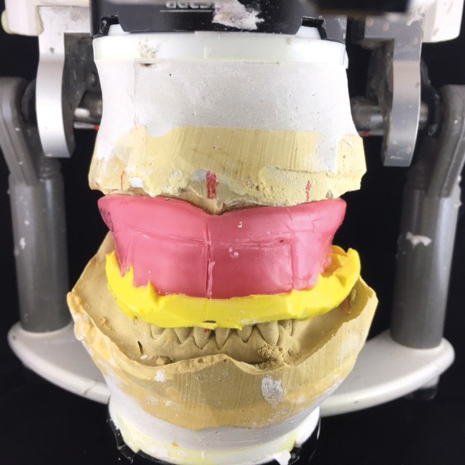

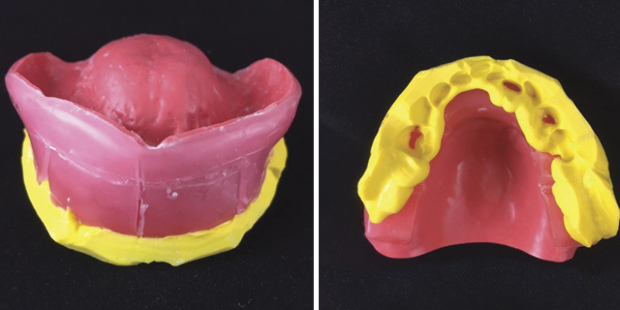

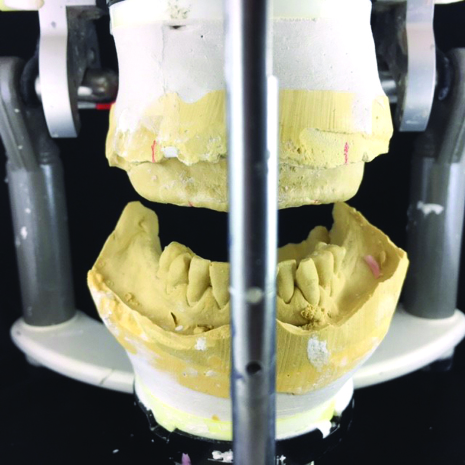

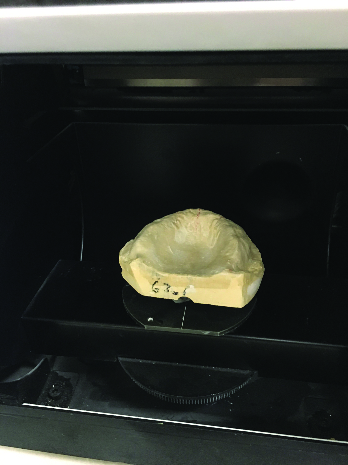

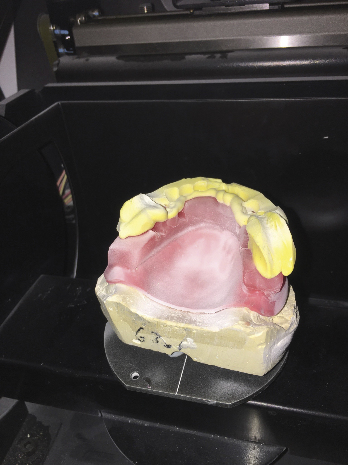

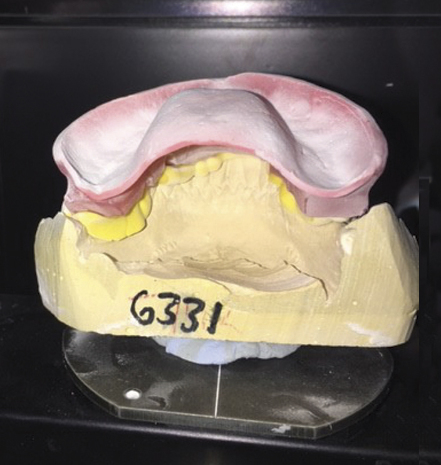

Guardiola then created a stabilized wax prototype shown above (the dentist requested the second molars be removed). He used a proprietary technique—developed and taught by Heraeus Kulzer—which involved removing the printed teeth from the printed prototype and then adding wax and the Mondial teeth onto the printed prototype base.Final Result:

After the try-in, Guardiola made one minor adjustment to the vertical dimension (the bite was closed less than 1mm) and created the final denture by converting the prototype using Heraeus Kulzer’s proprietary injection process. This proprietary conversion process can also be used with pouring or press-packing techniques.

The dentist and patient were pleased with the results. The patient raved about the fit, and the dentist appreciated that the prototype process involved less than 10 minutes of chairtime.

The laboratory also realizes significant labor savings with the process and hopes to eventually convert all of its dentist-customers from analog dentures to My Digital Dentures, with each practice beginning with some single-arch denture cases. Guardiola also says it will be easier to train denture technicians since the software is smart and digitizes many of the fabrication steps, and praises Heraeus Kulzer’s support in helping him implement and market the system.

Contact Information: Call 800-431-1785 or visit www.heraeus-kulzer-us.com.